Discover "Panelok" Flat Pack Building Systems

Build Faster, Smarter and Greener

with Panelok™ Flat Pack Building Systems

Distributed by Patterson Built

Bringing world-class, Australian-engineered flat-pack building technology to builders, architects and developers across Australia. With over two decades of high-end construction experience, we now support the industry by supplying the Panelok™ system — a faster, greener, structurally superior way to build.

Industry Experience. Smarter Solutions. Superior Support.

Patterson Built has been known for years as a high-end, detail-driven construction company with deep expertise across custom homes, renovations and complex architectural builds.

That experience now fuels our new role as a trusted distributor of Panelok in Australia.

Panelok™ is an internationally patented, Australian-made flat pack building systems designed to help builders and developers deliver stronger, greener and more efficient projects — without the delays, trade shortages or cost blowouts associated with traditional construction.

Our goal is simple:

To support the building industry with innovative products, technical clarity and exceptional customer service, backed by real-world, on-site experience.

What Is the Panelok Flat Pack Building Systems?

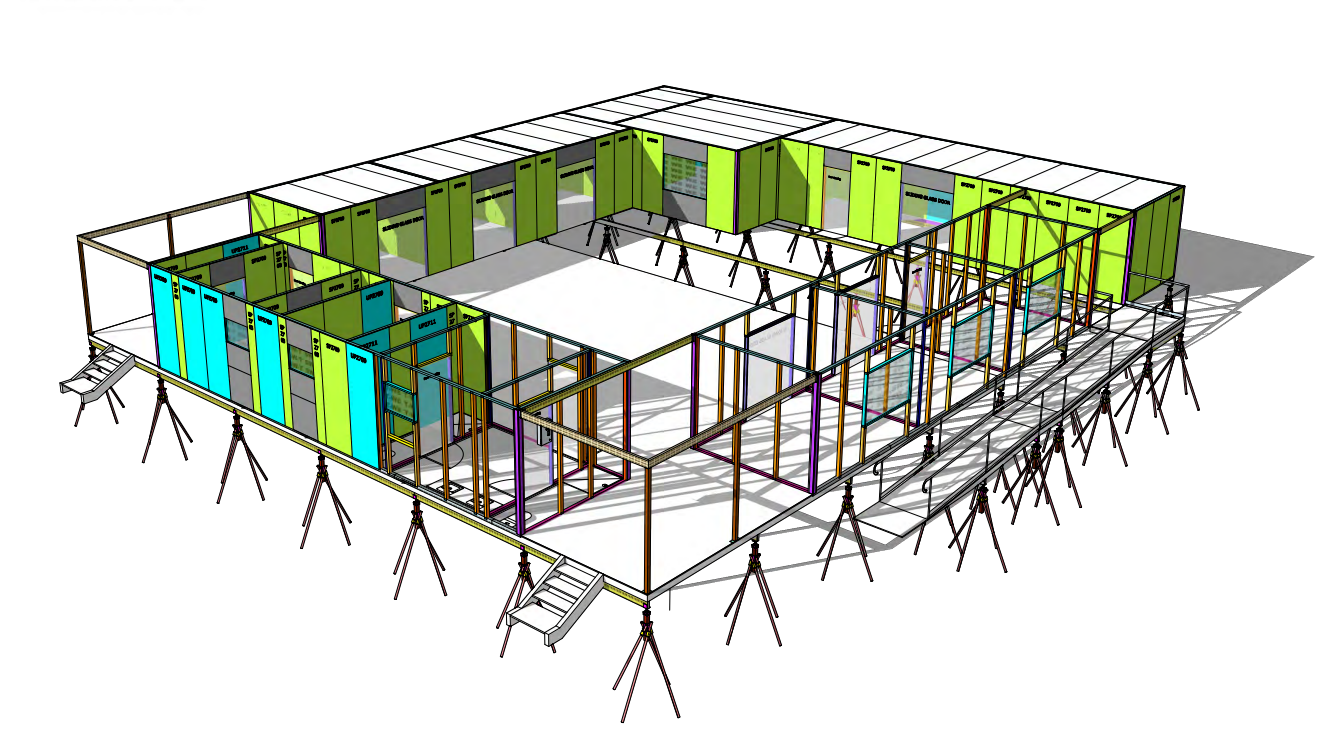

Panelok™ is an internationally patented, fully engineered flat-pack building system that enables high-quality homes and multi-dwelling projects to be constructed and achieve the lockup stage in a fraction of the time of conventional building.

At its core is a structural insulated wall panel (SIP) system, manufactured in Australia using:

• BlueScope TrueCore® steel framing

• A fire-resistant insulated core

• High-impact, non-combustible cladding on both faces

Panelok components arrives on site as a complete, coordinated structural package — including engineered floors, platform floor systems, roof trusses, fixings and finishing products based on your project requirements.

As your authorised distributor, we supply everything you need to integrate the Panelok system into your project, while supporting your team with technical guidance and clear documentation.

Why Choose Panelok

Panelok flat pack building system was designed around the real-world pain points builders face — labour shortages, lengthy timelines, structural complexity, rising material costs and inconsistencies in quality.

Here’s how the system solves them:

Build in Around Half the Time

Pre-finished, precision-made panels and a streamlined installation process allow builders to reach lock-up significantly faster — meaning fewer delays, smoother sequencing and more predictable timelines.

Improved Project Cashflow

Faster builds mean faster progress milestones. Developers and builders can complete projects sooner, reduce holding costs and move onto the next job earlier.

Reduced Trade Dependencies

Panelok system and components simplifies the supply chain — fewer trades required, less coordination, fewer bottlenecks and more reliability on site.

Superior Energy Performance

SIP construction supports 8–10-star energy ratings, offering a major advantage under tightening NCC requirements and increasing environmental expectations.

High Strength & Resilience

Constructed with BlueScope TrueCore steel for durability and structural integrity. Engineered for cyclonic regions up to C4 and designed to resist fire, moisture, termites and mould — supporting safer, more durable builds.

Limitless Design Possibilities

From bespoke homes to multi-storey projects, Panelok supports every architectural style and site, offering total design freedom and millimetre perfect precision.

Non-Combustible & Fully Insulated

Panelok Structural Insulated Panels (SIP) feature fire-resistant cladding, thermal insulation, and integrated acoustic protection — delivering safer, quieter, energy-efficient spaces.

Thinner Walls, More Living Space

Where brick veneer walls take up 230–250mm, Panelok’s thinner structural external walls are 100mm thick, gives that space back to the interior—often adding 5–7m² to the home without increasing the footprint.

Australian Made & Fully Engineered

Manufactured to Australian standards with local engineering, local steel and a patented system designed specifically for the Australian environment.

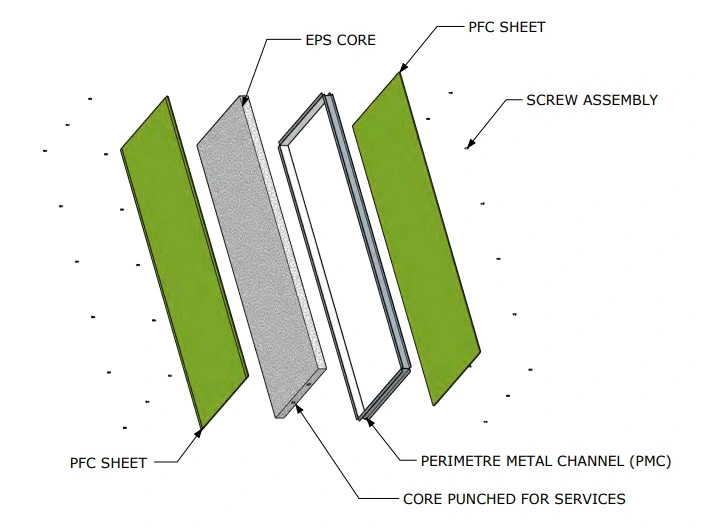

Panelok Wall System

Panelok’s wall system uses fully engineered structural insulated panels (SIPs) designed for fast, precise building. Each panel includes a fire-resistant EPS core, a full BlueScope TrueCore steel frame, and dual 10mm high-impact cladding laminated to both sides.

Panels come in four standard widths (300, 600, 900, 1100mm). Once installed, the structure reaches lock-up remarkably fast, with walls immediately ready for paint, render, or architectural finishes.

To streamline services installation, dedicated service panels and engineered connection points allow electrical and plumbing runs to be installed cleanly without compromising the structure—keeping the building envelope strong, insulated, and efficient.

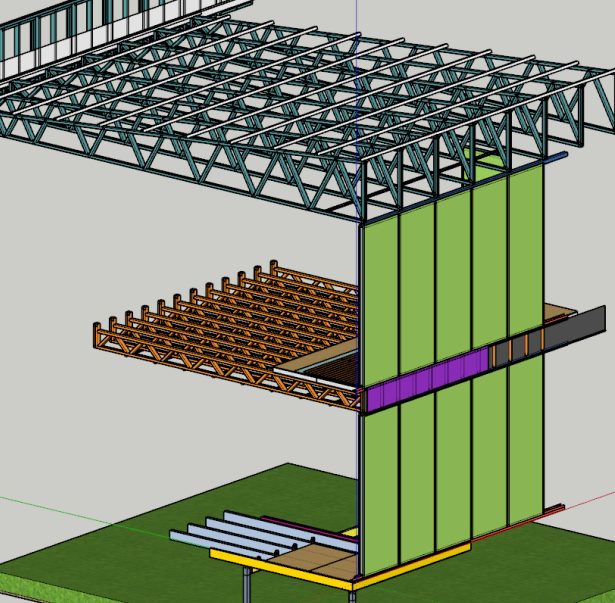

Panelok Floor System

Panelok’s floor solution combines its Steel Platform Floor System or Panelok Steel Floor Joists finished with its advanced 100mm thick Panelok's Insulated Panel Floor System laminated floor panels to create a stronger, quieter, and more efficient structure.

Panel Floor System is fully laminated panel with an insulated core and sheeted on both sides—featuring 10mm PFC sheeting tested to AS1530.1 and certified non-combustible on one face, and 15–19mm structural ply/PFC on the other. This provides a solid, concrete-like feel underfoot while remaining lightweight and fast to install.

Panels can be laid PFC-side up for tiled areas or ply-side up for secret-nailed timber flooring, ensuring the right substrate for every finish.

Panelok's Panel Floor System significantly reduces noise transfer between levels, eliminates squeaky floors, improves energy efficiency, and creates a robust, high-performance base that integrates seamlessly with the Panelok Wall System.

What We Supply as Your Panelok Distributor

Patterson Built supplies complete Panelok systems packages — helping you reach lock-up faster and with less on-site coordination.

Documentation:

- Engineering drawings & certificates

- Construction drawings

- Energy documentation

- 3D construction models (where applicable)

Structural Flat-Pack Materials:

- Panelok steel platform floor system

- Panelok insulated wall panels for internal and external walls

- Engineered floor systems for upper levels (bearers, joists, hardware)

- Roof trusses and roof framing components

- Roof, ceiling, and safety battens

- All required installation hardware.

Specialised Finishing Products:

- Panelok Impreg Sealer

- Panelok Ultra-Flex

- Base Coat, and Top Coat finishing products

OPTIONAL COMPONENTS (available based on project requirements) + -

- Aluminium windows and doors

- Metal cladding

- Fascia, gutters, barges, and flashings

Our Panelok Supply Process

A clear, streamlined process from enquiry to delivery — backed by practical, builder-minded support.

1. Share Your Plans or Ideas

Send us your concept plans, sketches, or even a rough idea of what you want to build. If you’re still early in the process, we can help you prepare a concept set to start with.

2. Receive a Free Preliminary Quote

Based on your plans and inclusions, we’ll prepare a preliminary quote for your project. This helps you understand what’s possible within your design and budget before committing.

3. Review & Finalise the Design

Once the quote is accepted, our drafting team prepares your preliminary concept drawings – including floor plans, elevations, and optional 3D views. You’ll review and approve these drawings before we move into detailed drafting.

4. Engineering & Energy Assessment

After your drawings are finalised, we coordinate with our engineering and energy efficiency teams to ensure your design meets all compliance and structural requirements. You’ll receive all relevant documents ready for approvals and certification.

5. Precision Modelling & Manufacturing

Once everything is signed off, Panelok’s manufacturing team prepares your steel-framed panel system precisely as per the approved design. Each panel is cut, checked, and packaged for efficient delivery and assembly.

6. Delivery Coordination

We’ll provide you with a delivery schedule, so that you could coordinate logistics to ensure your panels arrive on site ready to install. We could also assist you with organising the transportation if required. Every component is quality checked and labelled for easy on-site assembly.

7. Build with Confidence

Your Panelok kit arrives ready to install with a complete Installation Guide. We remain available for installation questions, documentation support and coordination with Panelok team if necessary throughout the build.

Technical Specifications & Documentation

Product Details & Installation Guides + -

Reports & Certifications + -

Safety Data Sheets + -

Order Panelok for Your Next Project

If you’re a builder, architect or developer wanting to integrate the Panelok™ system into your project, we’re here to support you.

Tell us a bit about your project and we’ll reach out with guidance, next steps, and the information you need to move forward.